HP Jet Fusion 3D printing represents a significant leap in the world of 3D printing technology, particularly in the realm of additive manufacturing. By leveraging its innovative Multi Jet Fusion technology, HP aims to disrupt traditional manufacturing processes such as injection molding, offering faster and more cost-efficient solutions. The latest developments in HP 3D printer sales suggest a strong market potential, especially as the company works with a diverse array of resellers throughout North America and Europe. With a focus on industrial 3D printing, HP is not just enhancing rapid prototyping but is also opening new avenues for mass production. This revolutionary approach is backed by collaborations with industry giants like Nike and BMW, showcasing the diverse application possibilities of this groundbreaking 3D printing technology.

The realm of additive manufacturing has been transformed by the emergence of advanced 3D printing solutions such as HP’s innovative systems. As the company scales its Multi Jet Fusion offerings, it paves the way for a new standard in production efficiency and material versatility. Building on its established presence in the market, HP is enhancing its 3D printer sales strategy through an extensive network of partners, optimizing the availability of these cutting-edge machines to manufacturers. Moreover, the integration of electronics into printed parts signifies a major evolution in industrial 3D printing, pushing the boundaries of what is achievable in product design and functionality. The future of this technology promises not only accelerated production times but also a broadening of creative possibilities for industries worldwide.

Scaling Up Multi Jet Fusion 3D Printing Business

HP Inc. is making significant strides in advancing its Multi Jet Fusion 3D printing technology, aiming to position itself as a formidable competitor in the manufacturing landscape. This technology is poised to challenge established manufacturing techniques such as injection molding, which has long dominated the industry due to its efficiency in mass production. To facilitate this growth, HP is focusing not only on direct sales of its Jet Fusion printers but also leveraging a network of around 30 resellers in key markets across North America and Europe. This approach allows HP to reach a broader audience, increasing its penetration in the booming additive manufacturing sector.

Moreover, HP has recognized that building a robust channel partner ecosystem is critical to its success in 3D printer sales. As stated by Steven Nigro, president of HP’s 3D Printing division, a remarkable 80% of these channel partners are new to HP, highlighting the company’s proactive strategy to expand its reach. The establishment of more than a dozen 3D Printing Reference and Experience centers throughout the U.S. and Europe provides potential customers an opportunity to engage directly with HP’s industrial 3D printing products. These centers will play a pivotal role in showcasing the capabilities of Multi Jet Fusion technology, further driving customer adoption and interest.

Revolutionizing Additive Manufacturing with Jet Fusion

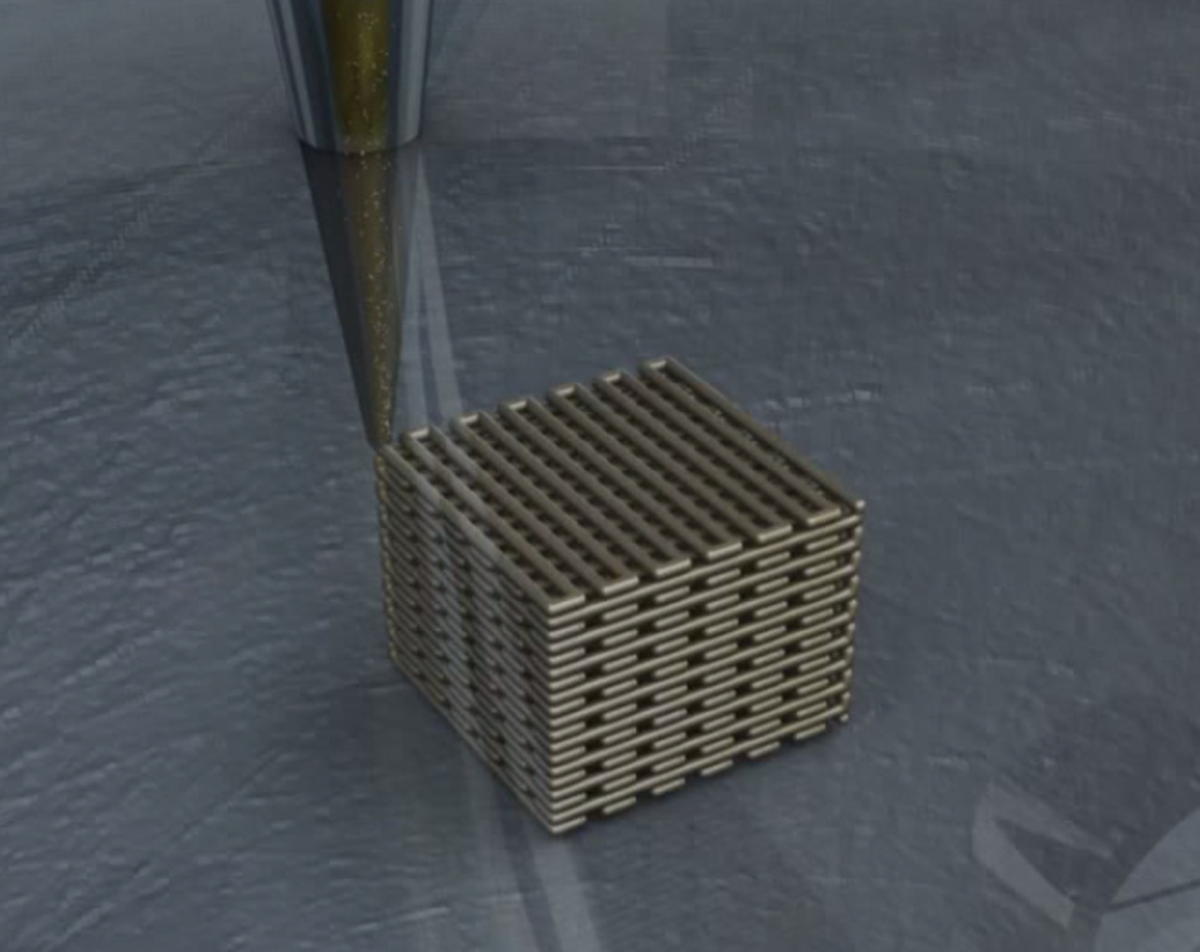

The introduction of HP’s Mult Jet Fusion 3D printers marks a transformative moment in the realm of additive manufacturing. Unlike traditional 3D printing methods that primarily focus on rapid prototyping, HP’s technology is designed for mass production. The ability to produce hundreds to thousands of parts significantly shifts the narrative around 3D printing, positioning it as a viable alternative to conventional manufacturing processes. HP’s approach utilizes advanced powder deposition techniques, creating layers that are only 100 microns thick, which is essential in achieving the high precision and sharp details necessary for commercially viable products.

HP’s Jet Fusion printers leverage a unique process where a print bar, equipped with 30,000 nozzles, strategically applies a fusing agent that enables the precise construction of complex geometries. Such capabilities mean that manufacturers can produce intricate parts with better speed and cost-effectiveness, thus enhancing their competitive edge in a crowded market. Furthermore, by integrating smart technology that allows for electronics to be embedded at the voxel level within the parts, HP is not only pushing the boundaries of 3D printing technology but also paving the way for innovative applications in diverse industries.

Key Partnerships and Collaborative Innovation

HP’s strategy to foster innovation in 3D printing is significantly bolstered by its collaborative efforts with leading companies across various sectors. Collaborations with industry giants such as Nike, BMW, and Johnson & Johnson underscore the versatility and potential of Multi Jet Fusion technology to cater to a wide range of manufacturing requirements. These partnerships are essential for testing and optimizing the Jet Fusion printers in real-world applications, ensuring that HP’s technology meets the rigorous standards expected in high-demand industries.

Additionally, HP has created an open platform aimed at enhancing material innovation and software development for its 3D printers. This initiative not only facilitates collaborative advancements but also focuses on establishing open standards for 3D printing materials, which is critical in reducing costs and improving print consistency across various applications. Companies expressing interest in collaboration, including Henkel AG and other material manufacturers, signal a growing ecosystem dedicated to pushing the boundaries of what’s possible with additive manufacturing.

The Economic Impact of HP Jet Fusion 3D Printing

The successful implementation of HP’s Multi Jet Fusion 3D printing technology not only stands to benefit individual businesses but also has larger economic implications for the manufacturing sector. By enabling faster prototyping and production times, HP’s technology aids companies in reducing their time-to-market, which is a crucial competitive advantage in today’s fast-paced economy. This resonates particularly well in industries where innovation cycles are short, and companies must rapidly adapt to changing consumer demands.

Moreover, with the potential to significantly lower manufacturing costs, HP’s Jet Fusion printers may democratize access to advanced production capabilities, allowing smaller companies and startups to compete with larger corporations. The displacement of traditional manufacturing processes by additive manufacturing could lead to job creation in sectors focused on 3D printing design, material development, and printing services. Thus, HP’s initiative in scaling its Multi Jet Fusion business presents a transformative opportunity to reshape the manufacturing landscape economically.

Technological Innovations in 3D Printing

HP’s Jet Fusion printers showcase groundbreaking technological innovations that set them apart from traditional 3D printing solutions. One of the most formidable advancements is the ability to print functional electronics directly into parts using conductive materials. This capability not only enhances the versatility of products manufactured through additive manufacturing but also opens pathways to new applications across industries such as automotive and consumer electronics.

Additionally, the use of voxels in HP’s 3D printing process is revolutionary. A voxel, which is akin to a pixel but in three dimensions, allows for fine-tuned control over the properties of each printed part. By manipulating voxels during the printing process, manufacturers can produce items with customized mechanical properties, surface textures, and even colors. This granularity and precision in material placement considerably elevate the standards for product functionality and design, propelling HP further as a leader in the evolution of industrial 3D printing.

Customer Engagement and Product Testing

To ensure that its Multi Jet Fusion 3D printing technology meets industry needs, HP has established a proactive customer engagement strategy that emphasizes product testing and feedback. By setting up multiple Experience Centers across North America and Europe, potential customers can directly interact with HP’s printers, witnessing firsthand the capabilities and advantages offered by the Jet Fusion technology. This engagement is crucial, not only for fostering customer relations but also for collecting valuable insights that can inform product improvements.

The hands-on experience available at these centers allows users to evaluate the speed, efficiency, and quality of 3D printing output in real-time. Through collaboration with a network of clients, including major brands and innovative startups, HP is paving the way for a feedback loop that drives continuous enhancement of its additive manufacturing solutions, ensuring they remain aligned with market demands and technological advancements.

Competitive Pricing Strategies and Market Penetration

HP is employing competitive pricing strategies to enhance its market penetration in the 3D printing domain. The introduction of its Jet Fusion printer series, specifically the 3200 and 4200 models, reflects a strategic approach to cater to various segments within the market. With a starting price of $130,000 for the entry-level model, HP aims to provide compelling value that justifies the investment for businesses looking to adopt additive manufacturing technologies.

Moreover, considering the potential for substantial cost savings in production processes, customers are made aware of the long-term ROI that can position HP printers as a worthwhile investment. This pricing approach is not only aimed at large manufacturing entities but is designed to attract small to medium-sized businesses that are increasingly exploring the adoption of 3D printing to enhance their operational efficiencies.

Addressing Industry Challenges and Standardization

While the prospects of 3D printing are promising, there are significant challenges that must be addressed for the technology to gain widespread adoption. HP recognizes that to establish its Jet Fusion technology as a reliable solution within the $12 trillion manufacturing marketplace, there is a pressing need for standardization in print quality and machine efficiency. Establishing industry benchmarks will be crucial in ensuring that customers can trust the consistency and reliability of 3D printing processes.

Additionally, HP is proactively working towards reducing the reliance on proprietary print materials, which can create barriers to entry for new users. By fostering an open platform for collaboration and driving innovation in 3D printing materials, HP is taking steps to alleviate these challenges, thus paving the way for a more inclusive and accessible additive manufacturing landscape.

Future Prospects for HP 3D Printing Technology

Looking ahead, the future of HP’s 3D printing technology seems poised for significant growth and evolution. With the ongoing advancements in the Multi Jet Fusion 3D printing systems, HP is well-positioned to capitalize on market demands for faster and more efficient production methods. The increasing awareness and adoption of additive manufacturing technologies across industries indicate a robust potential for HP to expand its footprint and influence in the 3D printing sphere.

As HP continues to innovate and refine its offerings, partnerships with material suppliers and product engineering companies will be vital to its long-term success. Such collaborations not only enhance the capabilities of Jet Fusion printers but also contribute to establishing a cohesive ecosystem capable of addressing diverse manufacturing needs. Overall, HP’s commitment to pushing the boundaries of 3D printing technology ensures that it will remain at the forefront of this dynamic and rapidly evolving industry.

Frequently Asked Questions

What is HP Jet Fusion 3D printing technology?

HP Jet Fusion 3D printing technology, also known as Multi Jet Fusion, is a revolutionary additive manufacturing method that enables the production of functional parts quickly and efficiently. This industrial 3D printing process uses a combination of powder, detailing, and fusing agents to create highly detailed, durable parts with reduced manufacturing costs.

How does Multi Jet Fusion compare to traditional manufacturing technologies?

Multi Jet Fusion by HP is designed to compete with traditional manufacturing methods like injection molding. It offers faster production speeds, cost efficiency, and the ability to manufacture complex geometries that are difficult to achieve with conventional techniques, thereby making it an exciting option for mass production.

What are the applications of HP Jet Fusion printers?

HP Jet Fusion printers are versatile and can be used for a wide range of applications, including automotive parts, consumer goods, and custom medical devices. Their ability to produce parts at scale makes them suitable for both prototyping and limited production runs, catering to various industries that require innovative manufacturing solutions.

What is the pricing for HP 3D printer sales like?

HP Jet Fusion 3D printers start at $130,000, with complete systems, including post-processing stations, priced up to $200,000. These price points allow businesses to consider industrial 3D printing for both prototyping and production-scale applications.

How does HP ensure quality in its 3D printing technology?

HP is committed to quality control in its Multi Jet Fusion process by establishing standards for print consistency and machine uptime. The company is also working on an open platform for collaboration with material partners to innovate and certify new materials compatible with HP Jet Fusion printers.

What companies are collaborating with HP on 3D printing technologies?

HP has a variety of collaborators ranging from industry leaders like Nike, BMW, and Johnson & Johnson to innovative service providers like Fast Radius and Materialise. These partnerships enable extensive testing and development of new applications for HP Jet Fusion 3D printing technology.

When was the first HP Jet Fusion printer announced and what milestones have been reached since then?

The HP Jet Fusion printer was first announced in October 2014. Notable milestones include the recognition of revenue from sales for the first time in 2017 and ongoing collaborations with various companies to enhance its offerings in the additive manufacturing sector.

What makes HP Jet Fusion technology unique in the field of industrial 3D printing?

HP Jet Fusion technology stands out due to its ability to print multiple materials simultaneously at the voxel level, enabling the incorporation of electronics into 3D printed parts. This capability offers unparalleled design flexibility and opens new avenues for innovation in additive manufacturing.

What should potential customers know before investing in HP 3D printer technology?

Before investing in HP Jet Fusion technology, potential customers should consider their production needs, the upfront investment required, and the potential for cost savings in manufacturing. It’s also beneficial to explore HP’s network of resellers and testing centers to better understand the capabilities of the printers.

Can HP Multi Jet Fusion printers be used for end-use parts production?

Yes, HP Multi Jet Fusion printers are designed for the production of end-use parts, not just for rapid prototyping. They can efficiently produce parts in volumes ranging from hundreds to thousands, making them suitable for limited production runs and functional components.

| Key Points | Details |

|---|---|

| HP Jet Fusion 3D Printing Milestone | HP Inc. recognized revenue from 3D printer sales for the first time in Q1 2017. |

| Focus on Scaling Up | HP aims to scale its Multi Jet Fusion business to compete with traditional manufacturing technologies like injection molding. |

| Sales Strategy | Majority of machines will be sold through 30 resellers, with 80% being new partners for HP. |

| 3D Printing Technology | Jet Fusion printers enable mass production of parts rather than just rapid prototyping. |

| Innovative Printing Features | Printers can print electronics at the voxel level, allowing for complex designs. |

| Print Area | Print area measures 16-in. x 12-in. x 16-in. with 2.4 teravoxels. |

| Printer Models | Two models available: 3200 series (lower-cost) and 4200 series (higher-capacity). |

| Pricing | Jet Fusion printers start at $130,000; complete systems can go up to $200,000. |

| Collaboration and Diversity | HP collaborates with companies like Nike, BMW, and Johnson & Johnson for testing. |

| Open Platform Initiative | HP aims to create an open platform for material innovations and software to decrease costs. |

Summary

HP Jet Fusion 3D printing is revolutionizing the additive manufacturing landscape by emphasizing scalability and versatility in production. As the company focuses on establishing its Multi Jet Fusion technology as a competitor to traditional methods like injection molding, it showcases a range of innovative features that enhance production efficiency while allowing for the integration of electronics at a granular level. This shift towards mass production capabilities and collaborative strategies with industry leaders signifies a significant step for HP in capturing a larger share of the manufacturing market.