The Continuous Build 3D Demonstrator is a groundbreaking system developed by Stratasys that revolutionizes the landscape of 3D printing by enabling mass production through a network of modular 3D printers operating simultaneously. This innovative cloud-based 3D printing platform allows for the seamless integration of expandable printer units, geared towards fulfilling diverse manufacturing needs in an efficient manner. As each unique “print cell” within the system can undertake its own specific task, businesses now have access to unparalleled mass customization capabilities, positioning Stratasys as a leader in additive manufacturing. Partners like Fathom and In’Tech are already testing this cutting-edge technology, looking to optimize their production runs and meet the increasing demand for custom parts. With the Continuous Build 3D Demonstrator, users can visualize a new era of additive manufacturing where production runs exceed traditional limits, enabling more flexible and responsive manufacturing processes.

The 3D Continuous Build Demonstrator represents a pivotal advancement in the domain of additive manufacturing, offering a scalable solution for modern production demands. As modular 3D printers come together to form a cohesive cloud infrastructure, it creates opportunities for organizations to achieve rapid prototyping and extensive manufacturing without the burden of traditional tooling. This service-oriented approach to 3D printing fosters a new paradigm where businesses can efficiently manage a high volume of customized parts on-demand. With the ability to process CAD designs securely in the cloud, manufacturers can streamline their operations while maintaining intellectual property security. The concept encapsulated by the Continuous Build 3D Demonstrator is redefining the manufacturing landscape, bridging gaps between conventional practices and the versatility of modern technology.

The Future of Cloud-Based 3D Printing

Stratasys is pioneering a movement towards cloud-based 3D printing by developing a service platform that operates modular printer units. This innovative approach aligns perfectly with the current demands for streamlined production processes, enabling businesses to harness the full potential of additive manufacturing. With cloud connectivity, users can manage multiple print jobs across various 3D printer units seamlessly, ensuring that operations are conducted at maximum efficiency.

Cloud-based 3D printing also introduces significant advantages for mass customization. As companies explore ways to personalize products at scale, this technology provides the flexibility to adjust designs and specifications with minimal effort. The ability to direct manufacturing requests through a centralized cloud service allows users to optimize the distribution of work among available print cells, which can operate concurrently to meet increasing production demands.

The Role of Modular 3D Printers in Manufacturing

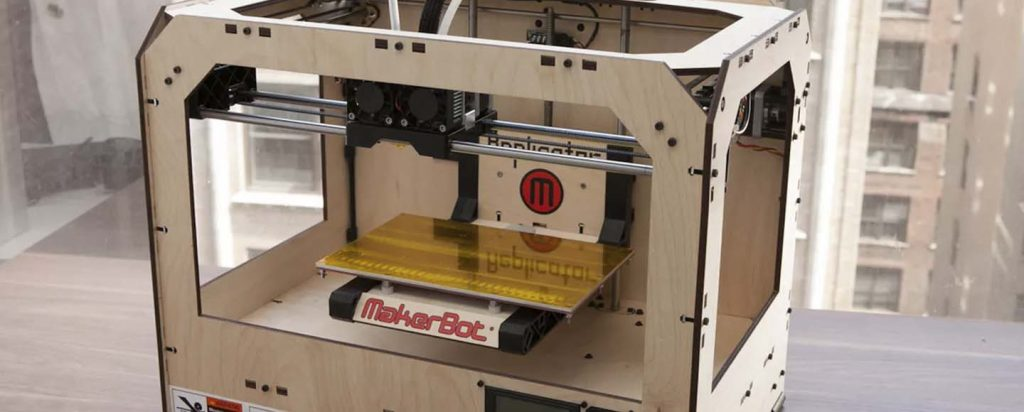

Modular 3D printers represent a transformative shift in production environments, particularly for companies that require scalability. The expandable design of Stratasys’ printers allows businesses to add additional units as their manufacturing needs grow, ensuring they can efficiently continue to produce high-quality parts without excessive lead times. This adaptability is crucial in today’s fast-paced market, where demand can fluctuate drastically.

Furthermore, these modular units can be configured to tackle different print jobs simultaneously. This capability not only enhances efficiency but also empowers manufacturers to achieve rapid prototyping and production of customized parts. The Continuous Build 3D Demonstrator embodies this approach, enabling operations that can handle varied project specifications while maintaining exceptional quality and reliability.

Continuous Build 3D Demonstrator: A Game Changer in Additive Manufacturing

The Continuous Build 3D Demonstrator is set to redefine additive manufacturing by offering a system where multiple 3D printers operate in tandem under a single management interface. This solution provides significant advantages for companies looking to scale their production capabilities while minimizing downtime. Each print cell can autonomously manage different jobs, essentially allowing for a production line that can pivot quickly to meet diverse customer needs.

This system is particularly beneficial for service bureaus and manufacturers facing challenges with traditional production methods. By leveraging the Continuous Build 3D Demonstrator, these companies can elevate their output, achieving manufacturing runs that exceed 1,000 parts with ease. The integration of Stratasys’ advanced Fortus FDM Printer technology into this system guarantees that the produced parts meet stringent quality standards necessary for contemporary manufacturing applications.

Mass Customization in Modern Production Environments

Mass customization has emerged as a prominent trend in manufacturing, allowing companies to meet customer demands for personalized products. The integration of Stratasys’ Continuous Build 3D Demonstrator plays a crucial role in facilitating this customization on a large scale. With its ability to manage multiple print cells, businesses can produce unique items with varied specifications without sacrificing efficiency.

The modular approach of the Continuous Build system validates the shift towards tailored production solutions, as companies can implement changes in design quickly and at lower costs. This approach enables quick adjustments to volume and complexity, leading to innovative product offerings that are adaptable to shifting market trends. As manufacturing evolves, the capability to customize while maintaining efficient production processes will be an essential component for businesses.

Ensuring Quality and Security in 3D Printing

As the production landscape increasingly shifts towards cloud-based services, the importance of quality and security in 3D printing is paramount. Stratasys prioritizes these aspects, ensuring that all designs submitted to the Continuous Build 3D Demonstrator are securely processed. Customers can upload their CAD files to the cloud for printing without concerns regarding intellectual property theft or unauthorized access by others.

Stratasys employs robust security measures and industry best practices to maintain the integrity of sensitive information throughout the printing process. This assurance allows customers to confidently utilize cloud-based manufacturing without compromising their proprietary designs or production processes. Quality assurance is further enhanced through the advanced Fortus printing technology, ensuring that the parts produced meet the highest standards required in various industrial applications.

Expanding Manufacturing Capabilities with Cloud Technology

The intersection of cloud technology and additive manufacturing is opening new doors for businesses seeking to enhance their manufacturing capabilities. By utilizing Stratasys’ Continuous Build 3D Demonstrator, facilities can transcend traditional constraints of manufacturing, embracing a more flexible, responsive production system. This technology allows manufacturers to operate remotely, sending job requests through the cloud for immediate processing, thereby reducing lead times.

Furthermore, the system’s architecture supports scalability, ensuring that businesses can keep up with evolving market demands. The ability to add print cells as needed means that manufacturers no longer need to rely on a fixed production capacity, allowing for dynamic adjustments based on real-time requirements. This adaptability is essential for companies aiming to stay competitive in an ever-changing economic landscape.

The Future of 3D Printing: Bridging Additive and Conventional Manufacturing

The Continuous Build 3D Demonstrator is emblematic of the future of 3D printing and its role in bridging the gap between traditional manufacturing methods and innovative additive processes. As more businesses look to integrate 3D printing into their operations, developments like those from Stratasys demonstrate the potential for hybrid manufacturing solutions that combine the efficiency of both approaches.

This convergence not only provides enhanced production capabilities but also fosters new possibilities for product development, allowing for quicker iteration and cost-effective manufacturing runs. As the industry embraces these advancements, the understanding and application of additive technologies will continue to reshape production methodologies, enabling businesses to deliver more value to their customers.

Utilizing GrabCAD Software for Optimized 3D Printing

GrabCAD software plays a fundamental role in the operation of the Continuous Build 3D Demonstrator by optimizing job management and print execution. By allowing users to easily upload and manage their CAD files, the software facilitates a smooth transition from design to production. Its user-friendly interface and integration with cloud technology greatly enhance workflow efficiency.

Moreover, the incorporation of GrabCAD ensures that job requests are directed intelligently, maximizing the utilization of available print cells across different sites. The system’s responsiveness allows for rapid adjustments to printing tasks, reflecting the dynamic nature of modern manufacturing. As users continue to adopt this software, it will redefine how they approach 3D printing tasks, making the process more seamless and productive.

Enhancing Production Strategies with Zero-Inventory Supply Chains

Zero-inventory supply chains are becoming increasingly important in contemporary production strategies, making the Continuous Build 3D Demonstrator an ideal solution for businesses looking to minimize costs while maximizing efficiency. This approach reduces the need for large inventories by enabling companies to produce parts on-demand, thus eliminating waste and enhancing cash flow. With Stratasys’ technology, manufacturers can efficiently manage production without overcommitting to physical stock.

By adopting these modern supply chain principles, organizations can respond more swiftly to changes in consumer demand, effectively positioning themselves in competitive markets. The ability to produce high-quality parts directly from digital designs also streamlines the overall manufacturing process, promoting significant cost reductions and improved operational flexibility. The impact of these strategies will continue to shape the future of production.

Frequently Asked Questions

What is the Continuous Build 3D Demonstrator by Stratasys?

The Continuous Build 3D Demonstrator is an innovative additive manufacturing platform developed by Stratasys that utilizes cloud-based technology and modular 3D printers. It allows multiple 3D print cells to operate simultaneously under a single software system, facilitating mass customization and enabling efficient, large-scale production of parts at various manufacturing locations.

How does the cloud-based aspect of the Continuous Build 3D Demonstrator work?

The cloud-based platform of the Continuous Build 3D Demonstrator processes manufacturing requests via a centralized service. When a request is submitted, it can be distributed across multiple 3D printers, or print cells, within the system, whether they are located in one facility or spread across different sites, ensuring high availability and efficiency in production.

What advantages does the Continuous Build 3D Demonstrator offer for mass customization?

The Continuous Build 3D Demonstrator enables mass customization through its scalable architecture, where each 3D printer can be dedicated to different print jobs simultaneously. This capability allows manufacturers to produce a diverse range of parts tailored to specific customer needs without changing equipment or tooling, thereby enhancing production flexibility and efficiency.

What are the specifications of the 3D print cells in the Continuous Build 3D Demonstrator?

Each print cell in the Continuous Build 3D Demonstrator can create objects measuring up to 5 inches x 5 inches x 5 inches. The system is designed to operate multiple cells concurrently, thus significantly increasing production volume and allowing for seamless transitions between different print jobs based on demand.

What types of businesses can benefit from the Continuous Build 3D Demonstrator?

The Continuous Build 3D Demonstrator is particularly beneficial for service bureaus, rapid prototyping centers, and volume manufacturing environments. Companies that are looking to enhance their production efficiency, minimize inventory costs, and provide customized parts quickly will find this additive manufacturing solution advantageous.

How does the Continuous Build 3D Demonstrator ensure intellectual property security?

Stratasys takes intellectual property security seriously with the Continuous Build 3D Demonstrator. All 3D CAD designs or STL files transferred to the cloud for printing are secured and not accessible to other customers, allowing businesses to confidently utilize the platform for their manufacturing needs.

Will the Continuous Build 3D Demonstrator be available for general use?

As of now, Stratasys has not specified an official launch date for the Continuous Build 3D Demonstrator for general sale. However, the system is currently being tested in collaboration with development partners, suggesting ongoing improvements before its widespread release.

What print technology is used in the Continuous Build 3D Demonstrator?

The Continuous Build 3D Demonstrator employs Stratasys’ production-class Fortus FDM Printer technology. This technology extrudes thermoplastic filament layer by layer to create high-quality, durable objects suitable for various manufacturing applications.

How does job management work in the Continuous Build 3D Demonstrator?

Job management in the Continuous Build 3D Demonstrator is streamlined via cloud connectivity. Users submit job requests in the form of CAD-generated files, which are then managed by the system to allocate tasks across the available 3D print cells efficiently. If a print cell fails, the job can be redirected to another cell without interrupting the workflow.

What future developments are anticipated for the Continuous Build 3D Demonstrator?

Future developments for the Continuous Build 3D Demonstrator may include enhancements in print cell capacity, improved cloud technology features, and broader industry partnerships. Stratasys aims to bridge the gap between traditional and additive manufacturing to create new value propositions for customers in various sectors.

| Key Point | Details |

|---|---|

| Cloud-service platform | Stratasys is developing a modular cloud-based platform for 3D printing. |

| Modular 3D printer units | The system includes expandable 3D printer units that operate under one software. |

| Mass production capability | Allows for mass production and customization of various parts through individual print cells. |

| Scalability | Additional print cells can be added anytime with no theoretical limits on the number of cells. |

| Industry partnerships | Collaboration with partners like Savannah College of Art and Design and production manufacturers. |

| Production improvements | Increased efficiency allows for manufacturing runs of over 1,000 parts. |

| Connectivity and software | Cloud-based software enables connectivity between units for job distribution. |

| Job management | Customers can submit CAD files for printing directly to the cloud service. |

| Intellectual property security | Assurance that CAD designs remain secure and inaccessible to other customers. |

| Integration of additive and conventional manufacturing | Stratasys aims to unify additive manufacturing with traditional production methods. |

Summary

The Continuous Build 3D Demonstrator represents a revolutionary step in the manufacturing landscape, showcasing Stratasys’ commitment to innovation in 3D printing technology. By integrating advanced cloud services with modular printer units, it offers unparalleled efficiency and flexibility for mass production. This system allows businesses to harness the power of additive manufacturing in a scalable and secure manner, ensuring that manufacturing requests can be executed swiftly, even across multiple locations. The potential applications are vast, ranging from rapid prototyping to large-scale production runs, appealing to various industries seeking to enhance their operational capabilities. As Stratasys continues to develop this technology, the future of 3D printing looks promising, with the Continuous Build 3D Demonstrator paving the way for efficient and sustainable manufacturing solutions.