3D printing in automotive manufacturing technology is revolutionizing the way car components are designed and produced. Ford, for instance, is at the forefront of this innovation, experimenting with the Stratasys Infinite-Build printer to create parts of virtually unlimited size. This breakthrough 3D printing process not only enhances the design possibilities but also significantly reduces the weight of automotive parts, like car spoilers, which can weigh less than traditional metal counterparts. By utilizing advanced materials such as carbon fiber, the potential for improving fuel efficiency and performance in vehicles is immense. As 3D printing becomes more integral to automotive manufacturing, it promises a future of custom-built car parts that are both efficient and affordable for consumers.

In the realm of vehicle production, additive manufacturing is emerging as a game changer, with innovators like Ford leading the charge. The advent of large-scale 3D printing technology, exemplified by the Stratasys Infinite-Build machine, allows manufacturers to construct extensive automotive components that were previously unattainable. With the ability to produce intricate designs with materials that enhance strength and reduce weight, the industry is witnessing the dawn of a new era in custom car part production. This technology not only streamlines the manufacturing process but also opens doors to refined prototype development for performance vehicles. As automotive companies embrace this cutting-edge technology, the landscape of automotive design is set for a radical transformation.

Ford’s Innovative Approach to 3D Printing in Automotive Manufacturing

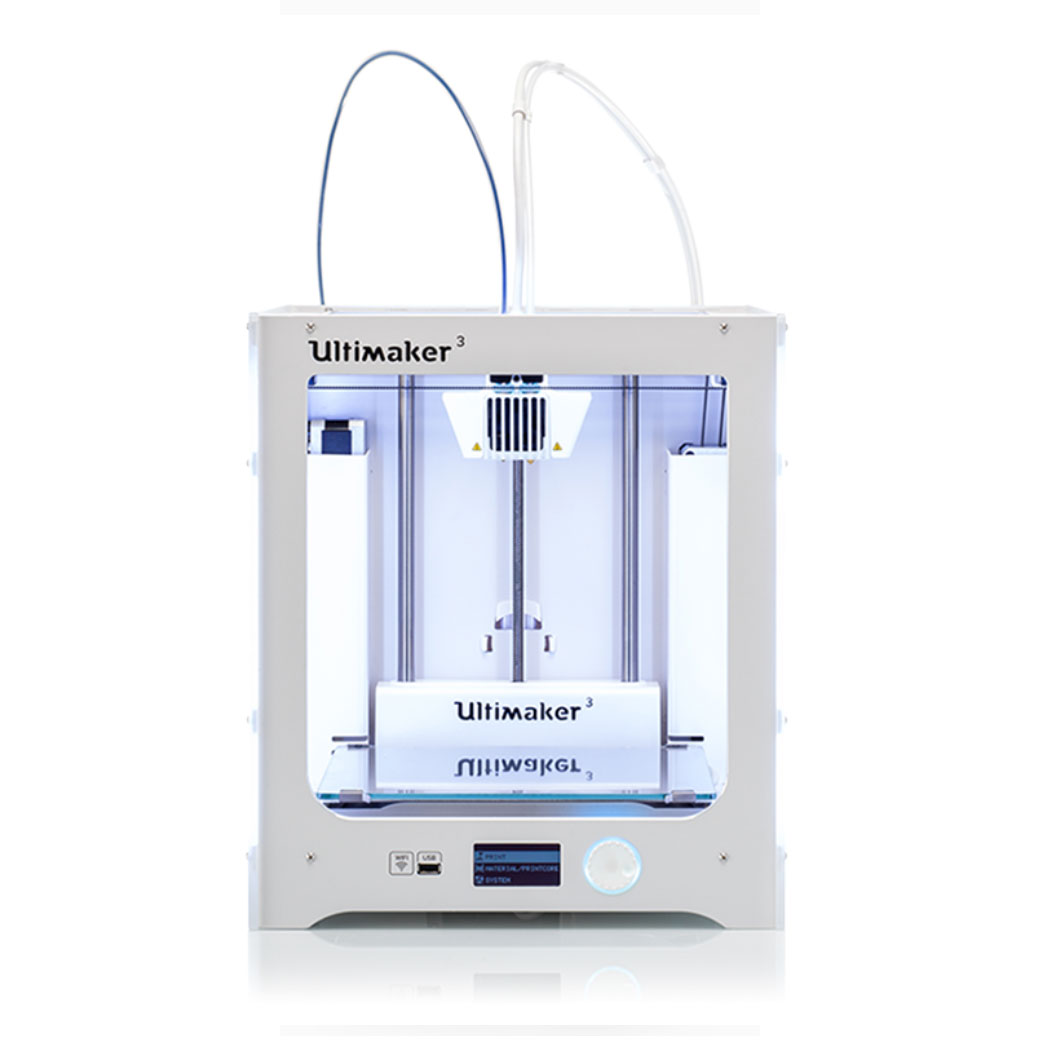

Ford Motor Company has made headlines by becoming the first automaker to actively test the revolutionary Stratasys Infinite-Build 3D printer. This groundbreaking technology promises to change the landscape of automotive manufacturing by allowing the production of parts that are virtually limitless in size. The introduction of this advanced 3D printing facility at Ford’s Research and Innovation Center in Dearborn, Michigan marks a significant milestone in the integration of cutting-edge automotive manufacturing technology. By utilizing this printer, Ford aims to explore the production potential of single-piece auto components that could enhance vehicle efficiency and performance.

As part of its innovation strategy, Ford is tapping into the potential of large-scale 3D printing to enhance the production of car parts. With the capability of creating complex shapes with high precision, this technology enables the creation of prototypes and tooling that is not only cost-effective but also efficient. By leveraging the strength and lightweight properties of materials like carbon fiber with the Infinite-Build printer, Ford could shift away from conventional parts manufacturing, leading to improved operational efficiency and potential reductions in costs.

The Advantages of Large-Scale 3D Printing for Automotive Parts

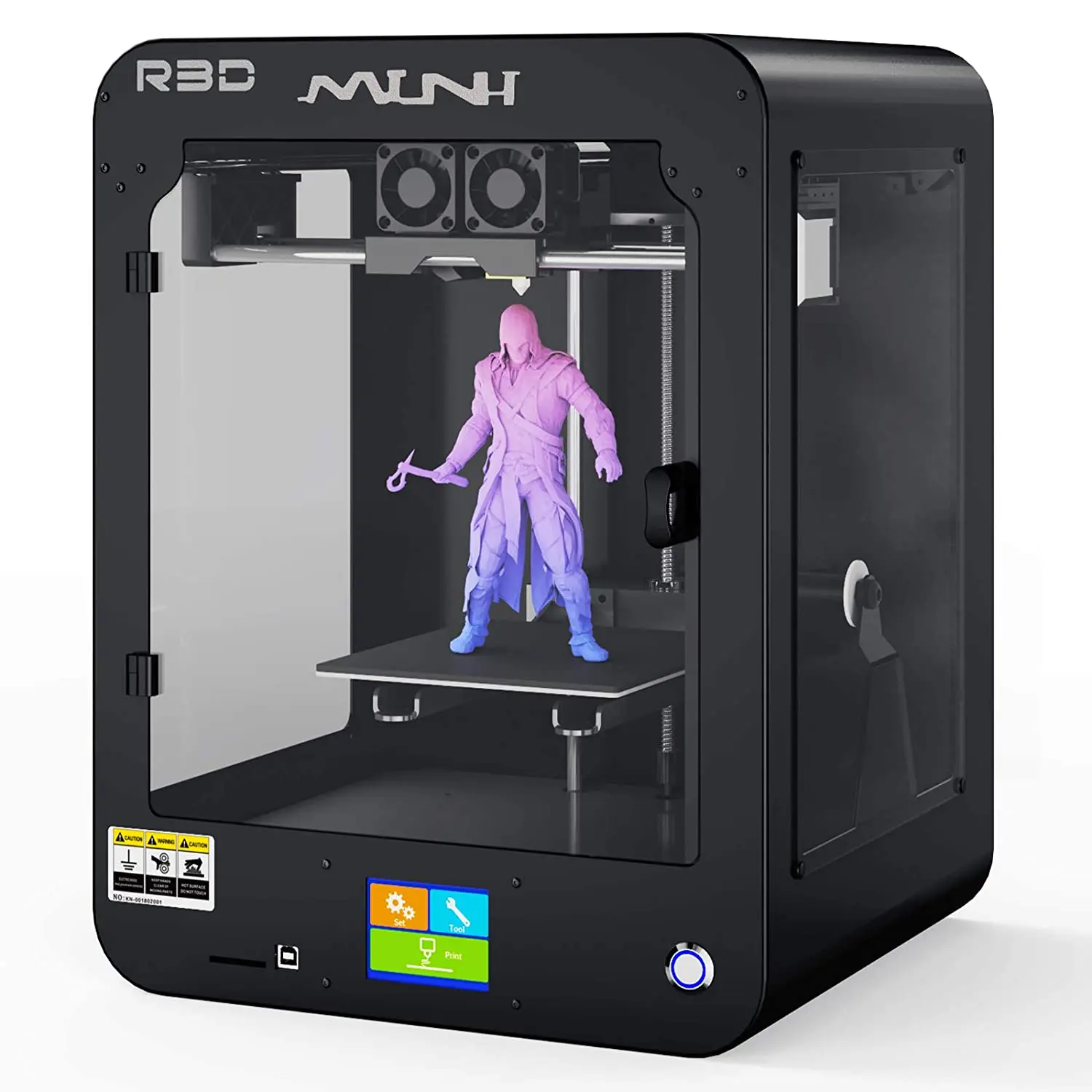

The Stratasys Infinite-Build printer offers several advantages that could transform the automotive industry. One of the most notable benefits is its ability to create larger components without compromising detail or strength. For instance, Ford’s ability to produce a 3D-printed car spoiler that weighs significantly less than its metal counterpart showcases the immense possibilities of this technology. 3D printing car parts not only reduces weight but also has the potential to improve fuel efficiency, which is a crucial factor in today’s environmentally conscious market.

In addition to weight reduction, large-scale 3D printing facilitates customization in automotive design, allowing manufacturers to produce low-volume parts tailored for specific vehicles. This is particularly beneficial for Ford Performance vehicles, as it enables the fine-tuning of components based on performance needs. The ability to manufacture car parts that meet unique specifications can enhance customer satisfaction and open new avenues for innovation within vehicle design and manufacturing.

Transforming Prototyping and Production with Advanced 3D Printing

Advanced 3D printing technology is revolutionizing the prototyping processes within the automotive sector. Ford’s integration of the Stratasys Infinite-Build printer allows for rapid prototyping, which accelerates the design process and minimizes lead times for new vehicle models. This capability fosters an environment where ideas can be quickly tested and brought to market, reducing the risk and costs associated with traditional manufacturing methods.

Moreover, as 3D printing for automotive applications becomes more efficient and affordable, manufacturers can focus on iterative design improvements without the constraints of traditional prototyping. This shift towards a more agile production model means that automakers like Ford can respond rapidly to market changes or consumer preferences, securing a competitive edge in a rapidly evolving industry.

Exploring Material Efficiency with 3D Printing in Automotive Parts

The choice of materials is crucial in automotive manufacturing, and the Stratasys Infinite-Build printer offers the ability to use advanced composites such as carbon fiber. This material is characterized by its strength-to-weight ratio, making it an ideal candidate for producing durable car parts. The utilization of such innovative materials in 3D printing not only allows for lighter components but also paves the way for enhanced fuel efficiency, which is increasingly important for modern vehicles.

Furthermore, employing composite materials in large-scale 3D printing demonstrates the industry’s commitment to sustainability. With the ability to manufacture parts with minimal waste and reduced energy consumption during the production process, automotive companies like Ford are leading the charge towards greener manufacturing techniques. This integration of innovation and environmental stewardship signifies a pivotal step in the future of automotive technology.

Ford’s Vision for the Future of Vehicle Manufacturing with 3D Technology

Ford’s exploration of 3D printing technology aligns with its broader vision of innovation and sustainability in vehicle manufacturing. By testing the capabilities of the Stratasys Infinite-Build printer, Ford aims to redefine traditional manufacturing methods, making them more versatile and efficient. The incorporation of this technology allows for a more streamlined process, from prototyping to production, enabling the company to stay ahead of the curve in a competitive automotive market.

The future of vehicle manufacturing 3D printing at Ford signifies not just technological advancement but also a commitment to enhancing consumer experiences. By offering more customized and lighter car parts that contribute to better fuel efficiency, Ford is positioning itself as a leader in automotive technology. This strategic move emphasizes Ford’s dedication to merging innovation with practical solutions, ultimately driving the evolution of the entire automotive industry.

The Role of Stratasys in Advancing Automotive Manufacturing Technology

Stratasys has played a pivotal role in advancing automotive manufacturing technology through its development of the Infinite-Build 3D printer. This printer addresses the need for larger-scale production while maintaining the mechanical properties required for automotive applications. As a partner in this groundbreaking venture, Stratasys enables Ford to push the boundaries of what is possible in car parts manufacturing, creating opportunities for enhanced design and engineering.

Additionally, Stratasys’ focus on aerospace and automotive sectors means that its technologies are tailored to meet specific industry requirements. The Infinite-Build printer’s unique capabilities allow for the precise production of complex geometries and structures, setting a high standard for future developments in 3D printing technologies. As Ford continues to explore these advancements, Stratasys will undoubtedly remain at the forefront of innovation in automotive manufacturing.

Benefits of Customization through 3D Printing in the Automotive Sector

The customization potential unlocked by 3D printing technology presents vast benefits for the automotive sector. Manufacturers like Ford are now able to create unique components that cater to specific customer needs or preferences. This level of customization not only enhances the user experience but also allows for the production of limited-edition models and bespoke vehicle features.

Moreover, the capacity for on-demand production means that manufacturers can respond more rapidly to consumer demands without the risks associated with excess inventory. This flexibility in production is particularly advantageous in today’s fast-paced automotive market, where consumer trends can shift quickly. With 3D printing, the automotive industry can adapt to these changes efficiently, ensuring that customer needs are met promptly.

Improving Efficiency through 3D Printing Automotive Components

As the automotive industry seeks to improve efficiency, 3D printing emerges as a key technology that addresses these goals. The use of the Stratasys Infinite-Build printer not only speeds up the production process but also enhances overall manufacturing efficiency. Since this technology allows Ford to produce larger components in a single piece, it reduces assembly time and complexity, streamlining the manufacturing workflow.

Moreover, the ability to quickly prototype and test car parts using 3D printing significantly decreases time-to-market for new vehicles. This acceleration in the development cycle enables automakers to introduce innovations faster and stay competitive. As 3D printing technology continues to evolve and become more integrated into automotive manufacturing processes, it’s anticipated that efficiency and product quality will continually improve, paving the way for future advancements in the industry.

The Future of Additive Manufacturing in the Automotive Industry

Looking forward, the future of additive manufacturing in the automotive industry is bright. As Ford and other manufacturers continue to explore the capabilities of 3D printing, we can expect to see a more widespread adoption of this technology across various segments of vehicle production. Innovations such as the Stratasys Infinite-Build printer will become integral to creating not just prototypes but also production-ready components that meet the increasingly demanding standards of the market.

Furthermore, as materials technology advances and production methods become more refined, the scope of parts that can be produced efficiently will expand. The incorporation of 3D printing into mainstream automotive manufacturing processes represents a significant shift towards more sustainable practices and greater design freedom. As these advancements unfold, the industry will likely witness a transformation in how vehicles are conceptualized, designed, and manufactured, ushering in a new era of automotive excellence.

Frequently Asked Questions

What is the significance of Ford 3D printing in automotive manufacturing technology?

Ford’s initiative in 3D printing represents a groundbreaking advancement in automotive manufacturing technology. By utilizing the Stratasys Infinite-Build printer, Ford can produce large-scale automotive parts and prototypes with unlimited dimensions. This technology allows for lighter and more durable components, which can significantly enhance vehicle performance and fuel efficiency.

How does car parts 3D printing benefit Ford’s production process?

Car parts 3D printing provides Ford with a cost-effective and efficient method for producing low-volume components and customizations for performance vehicles. This process streamlines production by enabling rapid prototyping and reducing material waste, which is essential for meeting the demands of modern automobile production.

What materials are typically used in automotive car parts 3D printing?

In automotive car parts 3D printing, materials such as carbon fiber are commonly used due to their lightweight and strong properties. The Stratasys Infinite-Build printer excels at processing these composite materials, creating parts that experience less shrinkage and warping, ensuring consistent quality and durability.

Can the Stratasys Infinite-Build printer be used for large-scale automotive components?

Yes, the Stratasys Infinite-Build printer is specifically designed for large-scale automotive components. Its unique screw extruder and horizontal build platform allow Ford to manufacture extensive car parts efficiently, overcoming the limitations of traditional vertical 3D printing methods.

How does 3D printing in the automotive industry improve fuel efficiency?

3D printing in the automotive industry, such as Ford’s use of the Infinite-Build printer, allows for the production of lighter car parts. For instance, components like spoilers can be 3D printed to weigh significantly less than their metal counterparts. This reduction in weight contributes to better fuel efficiency by requiring less energy to power the vehicle.

What advantages does 3D printing provide over traditional automotive manufacturing methods?

3D printing offers numerous advantages over traditional automotive manufacturing methods, including reduced production times, lower costs for low-volume custom parts, and enhanced design flexibility. Additionally, it allows for intricate part designs and the ability to produce lightweight components that improve vehicle performance.

Is Ford the only automaker investing in 3D printing technology for car parts?

While Ford is at the forefront with its Stratasys Infinite-Build printer, it is not the only automaker exploring 3D printing technology. Other companies like Boeing are also investigating similar capabilities for low-volume production of lightweight components, signaling a growing trend within the automotive sector.

What future developments can be expected in automotive 3D printing technology?

Future developments in automotive 3D printing technology will likely focus on more advanced materials, enhanced printing speeds, and greater precision in manufacturing processes. As these technologies evolve, they will further facilitate the use of 3D printing for large-scale production and more complex car parts.

| Key Points |

|---|

| Ford is testing Stratasys’ Infinite-Build 3D printer for parts of unlimited size. |

| The new printer aims to create prototypes of entire auto components. |

| 3D printing could revolutionize vehicle manufacturing with parts that are lighter, more durable, and customizable. |

| The use of carbon fiber in production reduces overall weight and enhances fuel efficiency. |

| Ford’s 3D printing operations are based in its Research and Innovation Center in Dearborn, Michigan. |

| The horizontal build platform allows for larger parts and improved assembly weights. |

| 3D printing becomes more cost-effective, particularly for low-volume and custom parts. |

Summary

3D printing in automotive is poised to revolutionize the industry, with Ford leading the charge by testing the innovative Stratasys Infinite-Build printer. This technology enables the production of large-scale, lightweight components that enhance durability and performance. By harnessing materials like carbon fiber, Ford aims to create more efficient vehicles while ensuring that manufacturing processes are adaptable and cost-effective. The future of automotive manufacturing is bright, as 3D printing continues to evolve, promising to deliver customized solutions and improved functionality in vehicle design.