3D printing in Veterans Affairs hospitals is revolutionizing patient care by enabling the creation of custom prosthetics, anatomical models, and innovative medical training tools with precision and efficiency. With the integration of Stratasys 3D printers for hospitals, VA facilities can now produce tailored orthotics and prostheses that address the unique needs of veterans. Not only do these advanced technologies enhance the quality of care, but they also facilitate collaboration across the VA network, allowing doctors and specialists to share and customize medical designs seamlessly. The use of 3D printers to create realistic training models empowers healthcare professionals to refine their skills, ensuring better outcomes for patients. As VA hospitals embrace this cutting-edge technology, they are setting new standards in personalized healthcare and medical innovation.

In the realm of healthcare, the integration of three-dimensional printing technology in Veterans Affairs facilities marks a notable shift towards personalized medicine. This innovative approach leverages advanced prototyping tools, enabling the development of tailored orthopedic devices and realistic educational models for medical training. By utilizing specialized desktop 3D printers, hospitals can produce intricate designs that directly address the individual needs of veterans, enhancing therapeutic outcomes. The collaborative opportunities presented through a central printing network further amplify the impact of accessible technology on patient care. As VA hospitals adopt this transformative technology, they are redefining standards in both medical practice and veteran support.

The Impact of 3D Printing in Veterans Affairs Hospitals

The integration of 3D printing technology in Veterans Affairs hospitals represents a groundbreaking shift in how medical care is delivered to veterans. By acquiring Stratasys 3D printers, these facilities are now able to create custom orthotics and prosthetics tailored specifically to the unique needs of individual patients. The collaborative network formed among these five core hospitals allows for an unprecedented exchange of resources and knowledge, enabling various locations to leverage 3D designs, even if they lack the physical printers. This innovation not only enhances patient care but also improves the accuracy and comfort of the devices being produced.

Moreover, the implementation of 3D printers at VA hospitals serves a dual purpose: it improves treatment diversification while training the next generation of medical professionals. The ability to print medical training models allows for more effective simulations of surgical procedures and hands-on practice without the risks associated with operating on real patients. This advancement in medical training fosters a more profound understanding of complex procedures and enhances the skill sets of doctors and medical students alike, which ultimately benefits patient outcomes.

Custom Prosthetics: Revolutionizing Patient Care

Custom prosthetics are transforming the lives of veterans by providing more comfortable, functional, and personalized solutions to limb loss. Traditional prosthetic devices often fail to cater to the precise anatomical needs of individual users, leaving many veterans dissatisfied with their fittings. Through the use of 3D printing technology, VA hospitals can now develop prosthetic limbs that are not only customized for anatomical fit but also lightweight and aesthetically pleasing. By utilizing advanced materials and design techniques from Stratasys, medical professionals can create prosthetics that closely mirror the original limb in both functionality and appearance.

In addition to comfort and fit, the speed at which custom prosthetics can be developed is also a game-changer. Instead of waiting weeks for a traditional prosthetic device to be manufactured, veterans can receive their personalized solutions in a fraction of the time, enabling them to resume their daily activities sooner. The modular approach facilitated by 3D printing allows for easy adjustments and repairs, further extending the lifespan of the prosthesis and ensuring that veterans always have access to the best care possible.

Medical Training Models: Enhancing Skills and Confidence

The ability to create realistic medical training models through 3D printing is enhancing the education and training of healthcare providers at VA hospitals. These models can accurately replicate human anatomy, allowing medical professionals to practice complex procedures before performing them on actual patients. The use of Stratasys 3D printing technology enables the production of low-cost, high-fidelity replicas that can be repeatedly used in training simulations, ensuring that every practicing clinician is well-prepared and confident in their skills.

Additionally, 3D printed training models can be tailored to specific patient conditions, providing targeted learning experiences that are highly relevant to the cases clinicians may encounter. For example, surgical teams can practice on modified models that reflect the anatomy of particular veterans needing surgeries, thereby increasing the likelihood of successful outcomes. This focus on personalized training not only boosts the confidence of healthcare providers but also emphasizes the VA’s commitment to using innovative technology to improve the quality of care delivered to veterans.

Collaboration Across VA Hospitals: A Network of Innovation

The establishment of a collaborative network among VA hospitals utilizing 3D printing technology is a revolutionary step forward in enhancing patient care. Each core hospital equipped with Stratasys Mojo printers can share digital files for prosthetics and training models with facilities that do not have their own equipment. This collaboration means that veterans from different regions can benefit from the expertise and resources available within this interconnected system, leading to improved access to specialized treatments and faster design-turnaround times.

Such collaboration fosters a culture of innovation within the community of VA hospitals, encouraging healthcare providers to share their experiences, challenges, and successes related to 3D printing. As the network grows, the insights gained can lead to the development of new techniques and practices that continuously refine patient care. This innovative spirit empowers doctors and researchers at VA hospitals to push the boundaries of what’s possible, ultimately creating more reliable and effective solutions for veteran patients.

Stratasys 3D Printing Technology: A Tool for Modern Medicine

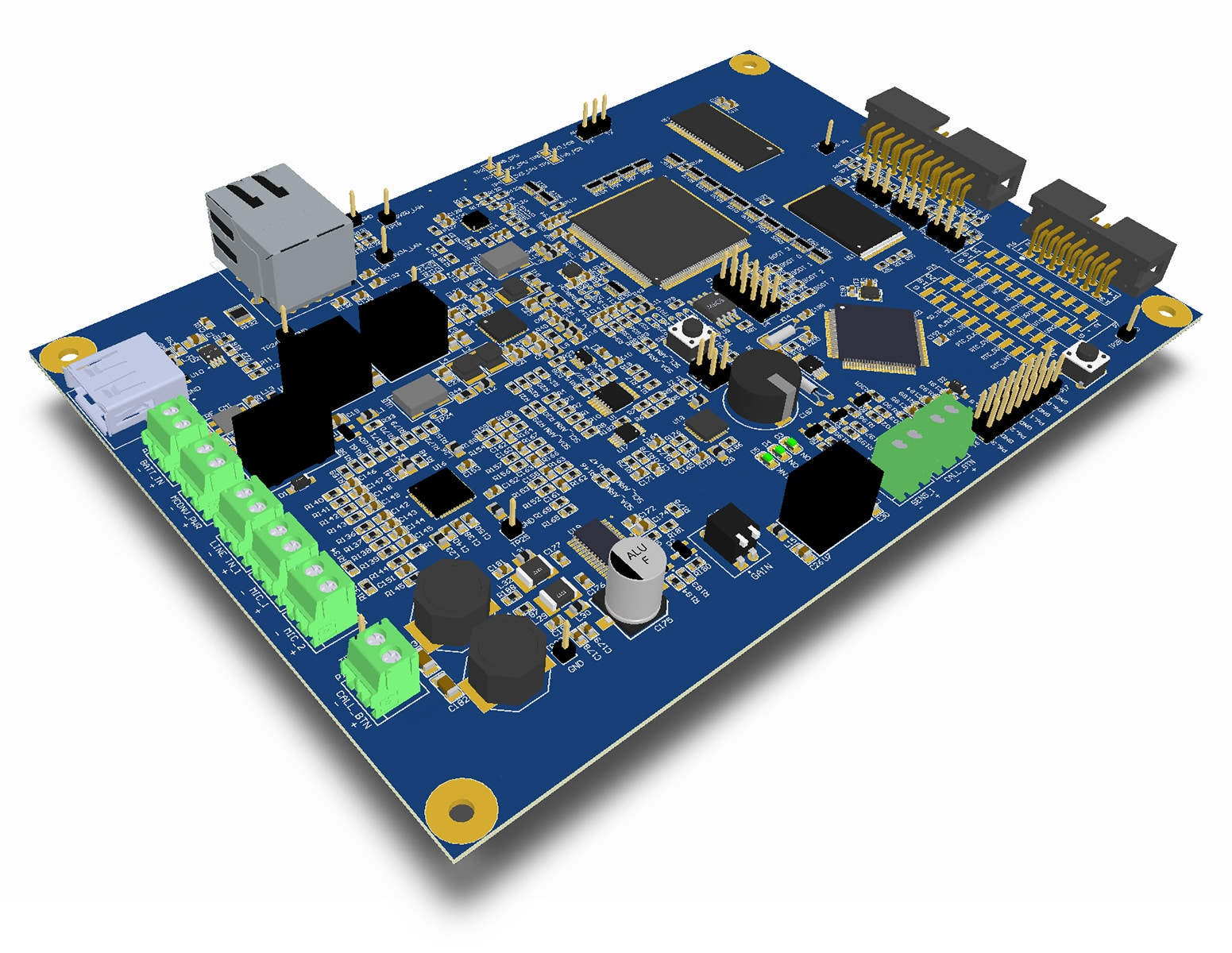

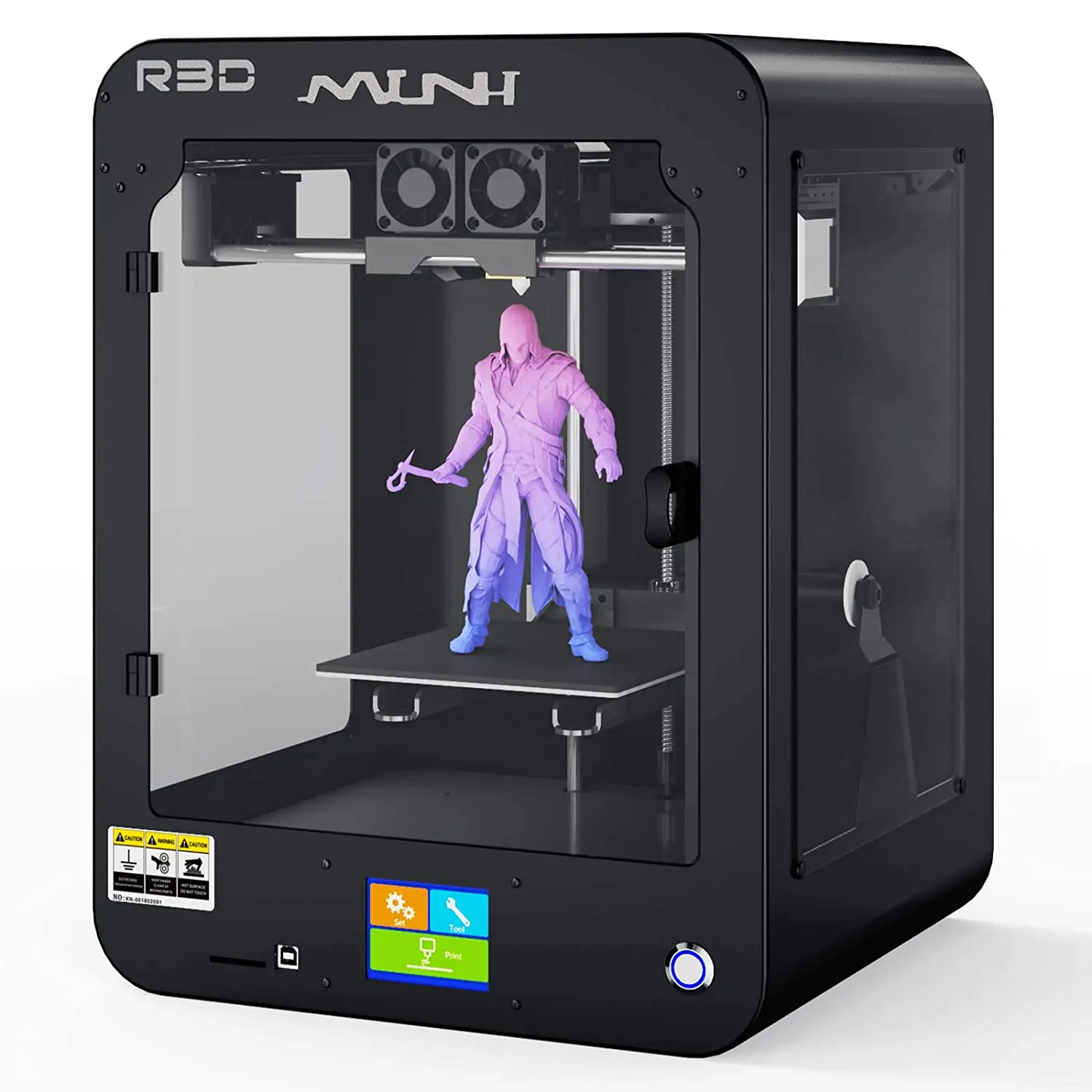

Stratasys 3D printers are at the forefront of modern medical technology, providing healthcare institutions like VA hospitals with state-of-the-art tools for precision healthcare deliveries. The Mojo Professional desktop 3D printer, in particular, has been instrumental in developing custom medical solutions that enhance both the operational efficiency and quality of patient care. By utilizing advanced fused deposition modeling, these printers allow for the creation of complex geometrical structures that are often impossible to achieve with traditional manufacturing methods.

The materials used in Stratasys printers help to accelerate the creation of medical devices while maintaining high standards of safety and functionality. The deployment of these printers simplifies the process of designing and iterating on orthoses and prosthetic devices, making it easier for medical teams to adapt and respond to the needs of their patients. This flexibility is essential in a field where individual anatomical considerations are paramount, ensuring that veterans receive devices that fit them perfectly.

The Future of 3D Printing at VA Hospitals

As 3D printing technology continues to evolve, its future within VA hospitals looks promising. With ongoing advancements in material science and printing capabilities, the potential for developing even more sophisticated medical devices and training tools will be realized. Future iterations of 3D printers are likely to incorporate more biocompatible materials, which will expand the application of printed devices in transplants and sensitive surgeries, offering veterans cutting-edge solutions that cater specifically to their health needs.

Furthermore, education programs focused on 3D printing technology are expected to proliferate within the VA hospital network. By training more medical professionals in utilizing these systems, the adoption of this innovative technology will only increase, leading to a broader range of applications in medical practice. As VA hospitals harness the power of 3D printing, it will undoubtedly reshape healthcare delivery for veterans, improving their quality of life and enhancing recovery outcomes.

The Role of 3D Printing in Veteran Rehabilitation

Rehabilitation for veterans often involves the need for functional mobility solutions, and 3D printing has emerged as a transformative aid in this process. Custom prosthetics designed and manufactured through 3D printing can substantially aid rehabilitation efforts by closely matching the individual needs of each veteran. These prosthetics can be designed to provide both comfort and functionality, ensuring that veterans can engage in their rehabilitation exercises without undue strain.

Additionally, the rapid prototyping capabilities of 3D printers enable healthcare providers to make real-time adjustments to devices as veterans progress through their rehabilitation. This adaptability not only caters to changing anatomical requirements during recovery but also empowers patients to be actively involved in their treatment. By fostering a partnership between patients and providers, 3D printing technology enhances the rehabilitation experience and supports veterans in striving for improved mobility and independence.

Cost Efficiency of 3D Printing in VA Facilities

Implementing 3D printing technology within VA hospitals can lead to significant cost savings over traditional manufacturing processes. The initial investment in Stratasys 3D printers quickly pays off in the long run, as producing custom prosthetic devices and anatomical models in-house reduces expenses related to outsourcing and lengthy wait times for materials. The ability to rapidly prototype and iterate on designs means that adjustments can be made affordably, enhancing the overall efficiency of the production process.

Furthermore, by creating devices that are tailored to specific patient needs, VA hospitals can minimize the number of adjustments and replacements typically required with one-size-fits-all approaches. This approach not only cuts costs but also leads to better patient satisfaction, as veterans receive devices that work for them right the first time. Overall, the integration of 3D printing in VA hospitals represents a sustainable investment in both patient care and financial management.

Advancements in Materials for 3D Printing in Healthcare

The selection of materials used in 3D printing is critical to the success of creating effective medical devices and training models. Stratasys has been at the forefront of developing innovative materials that meet the unique requirements of healthcare applications, such as biocompatible polymers that can be safely used in medical implants. These advancements in materials science enhance the potential for creating functional, durable, and safe prosthetics and medical models, helping VA hospitals to provide superior patient care.

In addition to biocompatible materials, ongoing research is likely to yield new composite materials that improve aspects such as flexibility, strength, and aesthetics of printed devices. As VA hospitals continue to adopt these advancements in materials, they will also expand the range of custom solutions they can offer to veterans, allowing healthcare providers to address a wider array of conditions and ensure that treatment plans are uniquely catered to individual patients.

Frequently Asked Questions

How is 3D printing being utilized in Veterans Affairs hospitals?

3D printing in Veterans Affairs hospitals enhances patient care by enabling the creation of custom prosthetics, orthotics, and medical training models. With Stratasys 3D printers, VA hospitals can produce tailored devices and anatomical models that meet the unique needs of veterans. This technology fosters collaboration among hospitals, allowing designs to be shared and adapted across the network.

What types of custom prosthetics can be created using 3D printing technology at VA hospitals?

3D printers for hospitals, specifically Stratasys Mojo printers, allow for the production of various custom prosthetics designed to fit the individual anatomical requirements of veterans. This includes prosthetic limbs and other assistive devices that can be rapidly prototyped and modified based on patient feedback.

Are 3D printed medical training models used in VA hospitals?

Yes, 3D printed medical training models are extensively used in Veterans Affairs hospitals. These models, created using 3D printing technology, help medical professionals enhance their skills and improve the accuracy of patient diagnosis and treatment procedures through realistic simulations of complex anatomical structures.

What role does Stratasys play in advancing 3D printing in Veterans Affairs hospitals?

Stratasys plays a pivotal role in advancing 3D printing technology in Veterans Affairs hospitals by providing state-of-the-art Mojo 3D printers, along with necessary materials and training. This partnership enables VA hospitals to utilize 3D printing for creating custom medical devices and models, enhancing patient care and medical training.

How can VA hospitals that do not have 3D printers still benefit from 3D printing technology?

VA hospitals without their own 3D printers can still access 3D printing technology by collaborating with core sites equipped with Stratasys printers. They can send 3D design files to these hospitals, allowing them to produce necessary prosthetics or medical training models, thereby extending the reach of this innovative technology network.

| Key Points |

|---|

| Five VA hospitals equipped with 3D printers for customized medical solutions. |

| Core hospitals: Puget Sound, San Antonio, Albuquerque, Orlando, and Boston. |

| Stratasys Mojo 3D printers: Fused deposition modeling technique. |

| Materials and training provided by Stratasys. |

| Collaboration across hospitals allows sharing and customization of CAD designs. |

| 3D printing assists in creating orthotics, prosthetics, and anatomical models. |

| The Mojo printer retails for approximately $6,300 and weighs around 60 lbs. |

| Objects can be created up to 5″ x 5″ x 5″ in size using ABS plastic. |

| Significant advancements in patient treatment, personalized health solutions for veterans. |

Summary

3D printing in Veterans Affairs hospitals marks a revolutionary step in providing tailored healthcare solutions for veterans. With five hospitals actively utilizing Stratasys 3D printers, there is a notable shift towards creating customized orthotics, prostheses, and other medical models that enhance the quality of patient care. This initiative not only empowers VA doctors to develop patient-specific designs but also fosters a collaborative network where resources and expertise can be shared among hospitals. The integration of 3D printing technology is set to improve diagnosis, treatment, and overall healthcare delivery for veterans, ensuring that they receive the most personalized care possible.